| Steel Wire Rope Compositions and Pulley Ratios |  |

||

|---|---|---|---|

| Const. | Optimized D/d | Min. D/d | |

| 6x7 | 72 | 42 | |

| 17x7,18x7 | 51 | 34 | |

| 6x21 Fi | 51 | 34 | |

| 6x26WS | 45 | 30 | |

| 35x7 | 45 | 30 | |

| 6x25Fi | 41 | 27 | |

| 6x31WS | 39 | 26 | |

| 6x37 | 39 | 26 | |

| x36WS | 39 | 23 | |

| 6x41WS | 35 | 21 | |

| 8x19 S | 32 | 27 | |

| 8x25 Filler | 41 | 21 | |

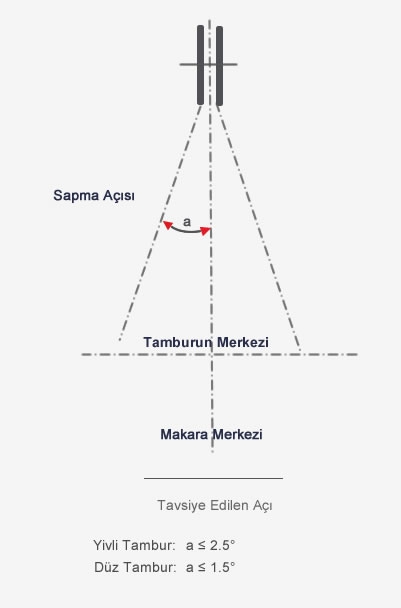

Fleet Angle

Fleet Angle: is the angle shown by the perpendicular line that goes from the center

of the chase to the drum flange and the drum center. Categorized as left and right.

The angle is expected to be in the recommended tolerance rates. Otherwise it affects

the wire’s service life.

To increase the performance and service life of wire, fleet of angle should be

1,5 angle on flat drums, and should not be more than 2,5 angle on grooved drums.

Lubrication of Wire Rope

Steel wire ropes are lubricated during production. However it is not sufficient for long term use. Therefore it should be inspected during maintanance and lubricated if necessary.

Advantages of Lubrication

1. Prevents wear

2. Increases life time

3. Protects against corrosion

4. Provides better slide of wires and strands during work olarak kaymalarını sağlamak.